Aujourd'hui, un article sur la fabrication de panneaux de carrosserie en métal. Je vous laisse le soin de traduire car je ne veux pas faire d'erreurs.

GUIDE TO FORMING THE WIDE-BODY SHQRP HQ’S PANELS

THE art of hand-forming sheet metal into

complex shapes almost seems like black magic in this age of high-volume

production and exotic materials. But thankfully there are those among us

who still know one end of an English wheel from the other and aren’t

scared of a planishing hammer.

Which brings us to Jamie Downie and Nate Browne from Kustom Garage in

Melbourne’s eastern suburbs. One of their biggest projects in the past

year has been creating the rear quarters and door skins on Peter Sharp’s SHQRP Monaro; a project that was sub-contracted out to them by the guys at Taree’s Down Town Kustoms (DTK). DTK

has been transforming this HQ Monaro into a wide-body supercar for well

over 12 months now, and stripped the shell right down to its skeleton.

We’ve covered some of the previous work in SM, June and July 2014, but

since then the guys have moved on to the massive rear quarters. Creating

these from scratch is difficult enough, but ensuring they are exact

opposites is a huge job, so DTK farmed it out to Jamie at Kustom Garage.

DTK

has been transforming this HQ Monaro into a wide-body supercar for well

over 12 months now, and stripped the shell right down to its skeleton.

We’ve covered some of the previous work in SM, June and July 2014, but

since then the guys have moved on to the massive rear quarters. Creating

these from scratch is difficult enough, but ensuring they are exact

opposites is a huge job, so DTK farmed it out to Jamie at Kustom Garage. “Graeme

came down with one of the original quarter panels off the car and

together we spent a week working to create the shape that they wanted.”

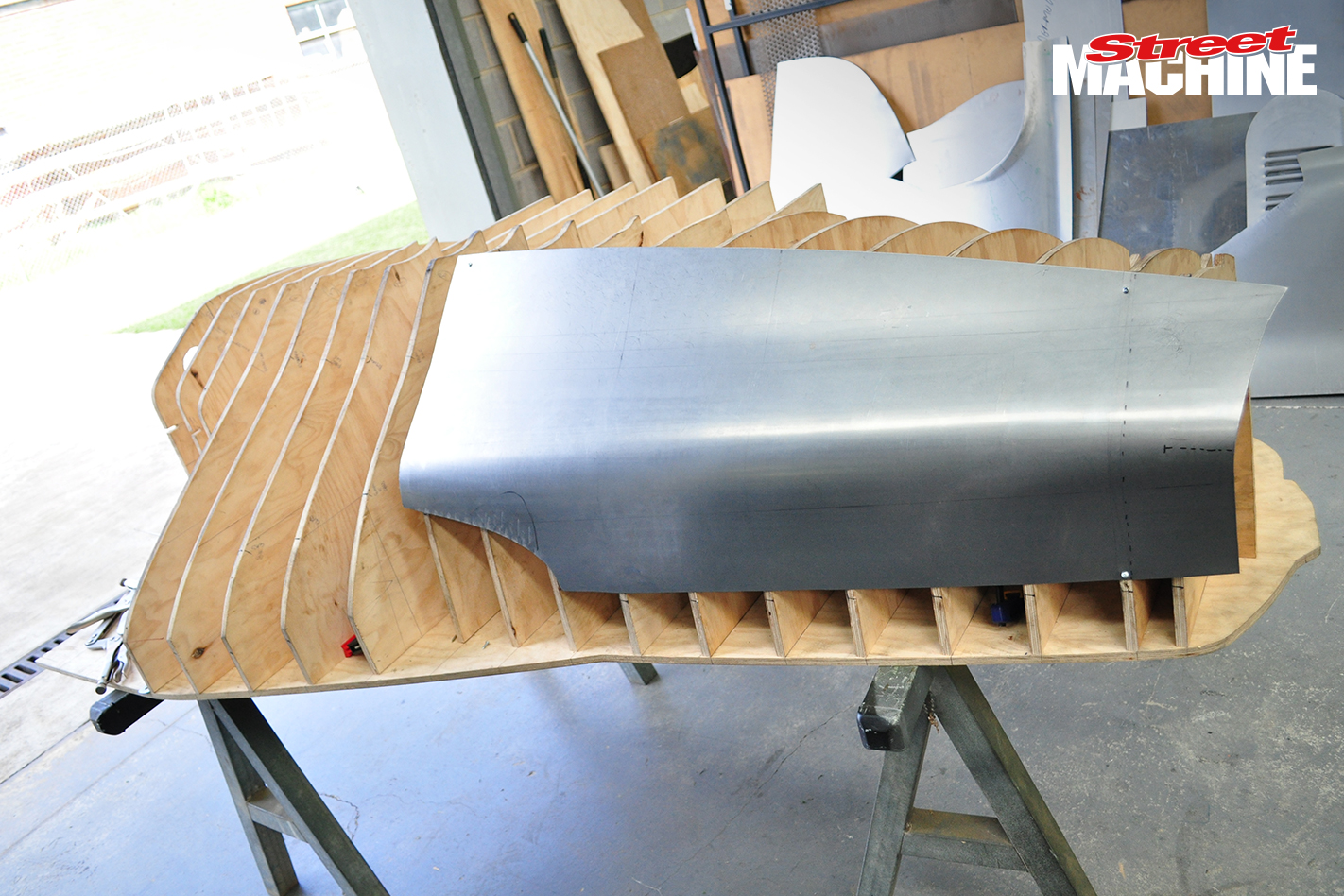

Once they had the shape sorted, Jamie and Nate created a wooden buck out

of thick plywood and used that to make reversible paper patterns and

templates so they could transfer the shapes to flat steel sheet and get

the job underway.

“Graeme

came down with one of the original quarter panels off the car and

together we spent a week working to create the shape that they wanted.”

Once they had the shape sorted, Jamie and Nate created a wooden buck out

of thick plywood and used that to make reversible paper patterns and

templates so they could transfer the shapes to flat steel sheet and get

the job underway. When

we joined the boys at Kustom Garage they had already finished the

passenger-side rear quarter and door skin on SHQRP. The original job was

to do just the quarter, but the door skins then needed to be redone to

smooth the transition from front to rear

When

we joined the boys at Kustom Garage they had already finished the

passenger-side rear quarter and door skin on SHQRP. The original job was

to do just the quarter, but the door skins then needed to be redone to

smooth the transition from front to rear Jamie

and Graeme worked together to create the sample quarter within a week.

They use that to create the wooden buck, and form the two quarters that

will eventually go on the car

Jamie

and Graeme worked together to create the sample quarter within a week.

They use that to create the wooden buck, and form the two quarters that

will eventually go on the car The

wooden buck outlines the shape of the rear quarter and is reversible by

swapping the pieces from one side of the backing board to the other

The

wooden buck outlines the shape of the rear quarter and is reversible by

swapping the pieces from one side of the backing board to the other Paper

patterns were created off the original sample panel. They show the size

and shape of each piece and are held in place by small magnets. When

laid on a flat piece of sheet steel the pattern is used to outline the

shape of each section

Paper

patterns were created off the original sample panel. They show the size

and shape of each piece and are held in place by small magnets. When

laid on a flat piece of sheet steel the pattern is used to outline the

shape of each section Jamie

uses a pen over the top of the paper templates to score out the shapes

of the four separate pieces that will make up the rear quarter, while

Nate uses masking tape to show the lines clearly

Jamie

uses a pen over the top of the paper templates to score out the shapes

of the four separate pieces that will make up the rear quarter, while

Nate uses masking tape to show the lines clearly Here

are the four pieces marked out on a fresh piece of 1mm CA3-grade steel

sheet. Creating the rear quarter out of one single piece is possible,

Jamie says, but would be much harder to manage due to its unwieldy size

Here

are the four pieces marked out on a fresh piece of 1mm CA3-grade steel

sheet. Creating the rear quarter out of one single piece is possible,

Jamie says, but would be much harder to manage due to its unwieldy size The

boys use an air nibbler to cut out the rough shapes quickly, staying

well outside the masking tape boundary. The size of the main sheet makes

it too hard to cut the pieces out with any kind of precision at this

point

The

boys use an air nibbler to cut out the rough shapes quickly, staying

well outside the masking tape boundary. The size of the main sheet makes

it too hard to cut the pieces out with any kind of precision at this

point Hand

shears are used to cut away the excess from each piece. Doing this by

hand is time consuming and tiring, but the precision is worth it. Then

the tape is peeled away and the edges are filed

Hand

shears are used to cut away the excess from each piece. Doing this by

hand is time consuming and tiring, but the precision is worth it. Then

the tape is peeled away and the edges are filed Here

are the four pieces in a flat arrangement as they will sit relative to

the HQ. There’s a stack of work to be done to create the necessary

curves and body lines – time to bring in the big guns

Here

are the four pieces in a flat arrangement as they will sit relative to

the HQ. There’s a stack of work to be done to create the necessary

curves and body lines – time to bring in the big guns The

biggest metal-shaping tool in Jamie’s workshop is Yoder, a 1942 power

hammer weighing in at three tonnes. It does the same job as an English

wheel – shaping panels – but uses a cyclical up-and-down motion

controlled by a speed-sensitive foot pedal. Definitely requires

ear-protection!

The

biggest metal-shaping tool in Jamie’s workshop is Yoder, a 1942 power

hammer weighing in at three tonnes. It does the same job as an English

wheel – shaping panels – but uses a cyclical up-and-down motion

controlled by a speed-sensitive foot pedal. Definitely requires

ear-protection! Remember

the paper patterns? Well they have measurements all along them that

correspond to points on each panel, and these cardboard templates are

used to check the shape of the curves

Remember

the paper patterns? Well they have measurements all along them that

correspond to points on each panel, and these cardboard templates are

used to check the shape of the curves The

buck also comes in handy for holding pieces in place. Here, Jamie has

the top of the rear quarter fixed in the correct position while he works

the back corner into shape

The

buck also comes in handy for holding pieces in place. Here, Jamie has

the top of the rear quarter fixed in the correct position while he works

the back corner into shape From

there it’s back to Yoder to shrink the metal of that same back corner.

“Other than speed, this is the main advantage of a power hammer over an

English wheel,” Jamie says. “You can stretch metal with an English

wheel, but you can’t shrink it”

From

there it’s back to Yoder to shrink the metal of that same back corner.

“Other than speed, this is the main advantage of a power hammer over an

English wheel,” Jamie says. “You can stretch metal with an English

wheel, but you can’t shrink it” The

Pullmax can do all kinds of things depending on the dies used. In this

case Nate is making a fold line on the edge of the panel. Like the power

hammer, the bottom die is stationary while the top die rapidly cycles

up and down

The

Pullmax can do all kinds of things depending on the dies used. In this

case Nate is making a fold line on the edge of the panel. Like the power

hammer, the bottom die is stationary while the top die rapidly cycles

up and down Not

everything can be done with power tools; there’s still plenty to do

with the good old hammer and dolly. The bag on top of the panel, filled

with lead shot, helps hold the piece in place

Not

everything can be done with power tools; there’s still plenty to do

with the good old hammer and dolly. The bag on top of the panel, filled

with lead shot, helps hold the piece in place The

shrinker/stretcher does exactly what you think. Two pairs of jaws clamp

on the edge and pull away from each other to stretch, or push towards

each other to shrink, which helps make curves in panel edges

The

shrinker/stretcher does exactly what you think. Two pairs of jaws clamp

on the edge and pull away from each other to stretch, or push towards

each other to shrink, which helps make curves in panel edges With

the two top pieces roughly in the correct shape, they’re screwed to the

buck in preparation for welding together. The two bottom pieces will

also be welded together to create an upper and lower section

With

the two top pieces roughly in the correct shape, they’re screwed to the

buck in preparation for welding together. The two bottom pieces will

also be welded together to create an upper and lower section With

two halves bent, beaten and pressed into shape, they’re screwed to the

buck and the overlapping material is removed. Any remaining excess is

trimmed away with hand shears so the two halves butt up against each

other

With

two halves bent, beaten and pressed into shape, they’re screwed to the

buck and the overlapping material is removed. Any remaining excess is

trimmed away with hand shears so the two halves butt up against each

other Now

the pieces are carefully TIGed together, with the buck holding them in

place. Jamie likes to tack the panels together first with no filler rod,

then he goes over all the joins with the rod

Now

the pieces are carefully TIGed together, with the buck holding them in

place. Jamie likes to tack the panels together first with no filler rod,

then he goes over all the joins with the rod And

here we are, the first time the rear quarter is together as one single

piece, but there’s plenty left to do. The boys don’t grind the weld off;

they work it with a hammer and dolly and then smooth it flat with an

adjustable body file

And

here we are, the first time the rear quarter is together as one single

piece, but there’s plenty left to do. The boys don’t grind the weld off;

they work it with a hammer and dolly and then smooth it flat with an

adjustable body file Time

to test-fit the panel to the car. It’s really starting to take shape

now and you can see where the custom bumper has been recessed into the

rear, requiring some modification to the panel

Time

to test-fit the panel to the car. It’s really starting to take shape

now and you can see where the custom bumper has been recessed into the

rear, requiring some modification to the panel The

bumper recess is clamped into place prior to welding. Because of the

shape, the recess has been created separately and needs to be welded in.

As before, Jamie will tack the piece into place using the TIG without

filler

The

bumper recess is clamped into place prior to welding. Because of the

shape, the recess has been created separately and needs to be welded in.

As before, Jamie will tack the piece into place using the TIG without

filler This

is precision welding. There’s no point dumping excessive heat into the

panel, especially with a non-structural piece like this. That just

creates more work; they don’t grind the welds smooth for the same reason

This

is precision welding. There’s no point dumping excessive heat into the

panel, especially with a non-structural piece like this. That just

creates more work; they don’t grind the welds smooth for the same reason The

last piece of the puzzle is the rear window sill, which has to be

formed separately before it’s welded into position. Imagine trying to

create all those curves while wrangling the whole panel around

The

last piece of the puzzle is the rear window sill, which has to be

formed separately before it’s welded into position. Imagine trying to

create all those curves while wrangling the whole panel around Hammers,

dollies and body files are the tools of the trade when it comes to

finishing off the sheet metal. But you’ll need a whole lot of

experience, skill and patience to create metal magic like you’ve seen

here

Hammers,

dollies and body files are the tools of the trade when it comes to

finishing off the sheet metal. But you’ll need a whole lot of

experience, skill and patience to create metal magic like you’ve seen

here And

here’s the finished product – or finished from Jamie’s end, anyway. The

whole job – from creating the buck to the completed rear-quarters and

door skins – took 350 hours, or to put it another way, nine weeks of

eight-hour days full-time

And

here’s the finished product – or finished from Jamie’s end, anyway. The

whole job – from creating the buck to the completed rear-quarters and

door skins – took 350 hours, or to put it another way, nine weeks of

eight-hour days full-time

Aucun commentaire:

Enregistrer un commentaire